Air Technology Systems Limited are design and project management specialists with over thirty years of experience in providing effective, energy saving systems for industrial Climate Control & Odour Control Solutions.

Client – Thames Water

We are working with MVB for Thames Water on the Lee Tunnel Project, London: the largest, deepest vertical tunnel in Europe.

Project Scope & Objectives

Air Technology Systems are providing both a specialist Industrial Ventilation Solution, combined with innovative rope access installation methodology within the new Main Shaft Pumping Station at Beckton Sewage Treatment Works, as part of the prestigious and ground-breaking Lee Tunnel Project.

The Lee Tunnel is the first of two tunnels being constructed for Thames Water, which will collectively capture sewage from various combined sewer overflows (CSOs), built by the Victorians as part of an ageing sewerage network that still serves London 150 years on.

The four-mile tunnel will run beneath the London Borough of Newham from Abbey Mills to Beckton, and it will help prevent more than 16 million tonnes of sewage mixed with rainwater overflowing into the river Lee each year, by capturing it and transferring it to Beckton Sewage Treatment Works, which is being expanded to enable it to deal with the increased volumes of sewage and flood water.

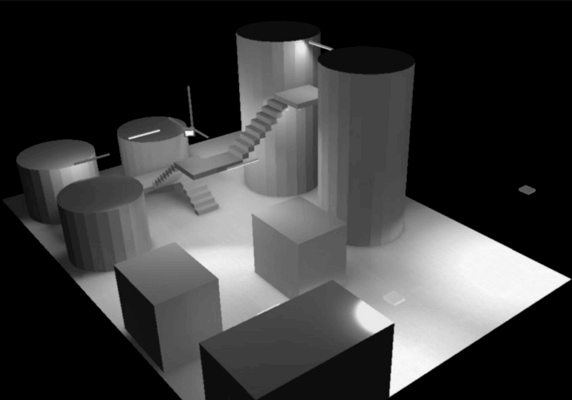

A new main shaft pumping station is being constructed within a 38m diameter, 80m deep shaft at Beckton and linked to the main Lee Tunnel. The main area of the Pumping Station will be divided into two dry well compartments which shall house the pumps and motors to pump the storm water into Beckton STW for treatment.

In addition, the pumping station has two designated access shafts to allow safe ingress and egress from the pumping station for maintenance.

Air Technology Systems have worked in the water industry as specialist ventilation and odour control providers for 20 years and were approached by MVB to quote for the ventilation for this specialist project.

Solution

Design

Air Technology Systems were chosen to deliver the ventilation package because of our innovative design and installation methods. The ventilation systems to serve the main shaft are designed to achieve a safe working environment for operatives due to the risk of hydrogen sulphide being present, but additionally to overcome the huge heat gain from the large pumps.

Air is supplied to both sides of the shaft via large plants located outside the shaft with large vertical ductwork being used to distribute air evenly throughout the drywells. We have further innovated using our original air induction nozzles which are key to achieving a high ventilation efficiency by thoroughly mixing the air, diluting any heat and contaminants such as hydrogen sulphide and creating the best possible working environment.

Air is extracted from low level from both sides of the shaft, another key design feature being that hydrogen sulphide is heavier than air and so collecting air at low level is another way we have increased the ventilation efficiency. Pumps are also located at low level and so we can capture heat at source and exhaust to outside.

The Access Shafts had different design requirements with a need to provide both general ventilation to the stairways, but also to pressurise the entire access shafts for firefighting. The system has been fully designed in accordance with BS EN 12101-6:2005 to provide a Class B system for means of escape and firefighting.

The design process has been challenging with lots of aspects to consider including selection of materials.

The entire main shaft ductwork system is 316 stainless steel sections to achieve a 20-year design life and with some of the ducts being 2.2m diameter we have used specialist construction techniques. Due to the depth of the pumping station replacement of ductwork will be very difficult and so selection of the correct materials is important.

The entire access shaft ductwork systems are 316 stainless steel sections, but fire rated for 4 hours.

Installation

Probably the biggest challenge on this project was how we would safely complete the installation. Conventional methods such as scaffolding and man riders were considered, but it was impossible to use this method because of the space available and of course would have a larger environmental impact using two cranes.

Installation via rope access was devised as the ideal solution as it allows access to install pipework, electrics, and ventilation systems within areas where scaffolding would traditionally be required, but would be inappropriate, prohibitively expensive, or unsafe.

At about the same time as this, an A/C system was being fitted on the 9th floor, in a light-well of a building that had multiple owners/landlords. The time taken to receive the necessary permissions to erect scaffold would have meant costly delays to the project.

Both challenges were overcome with a new innovative solution: the combination of IRATA rope access methods with the technical trade skills our operatives already had. Combining two existing skills is a major innovation in construction that has led to ATS being able to solve problems and provide solutions on both small and very large scales.

The Air Technology Systems rope access team is the only one in the World that can install the huge ventilation system on The Lee Tunnel Project, in the required location.