The scope of project was to provide tight temperature and humidity control to a processed printing site in Dunstable.

Client – RSR Ltd

Offering a full solution from construction to completion with Air Technology Systems, with both Mechanical design & Installation support.

Project Scope

The scope of project was to provide tight temperature and humidity controlled to a processed printing site.

This site was for a world-renowned global distribution company to enable them to print books to ensure ink for text and glue for book spine was at suitable conditions.

Our Services:

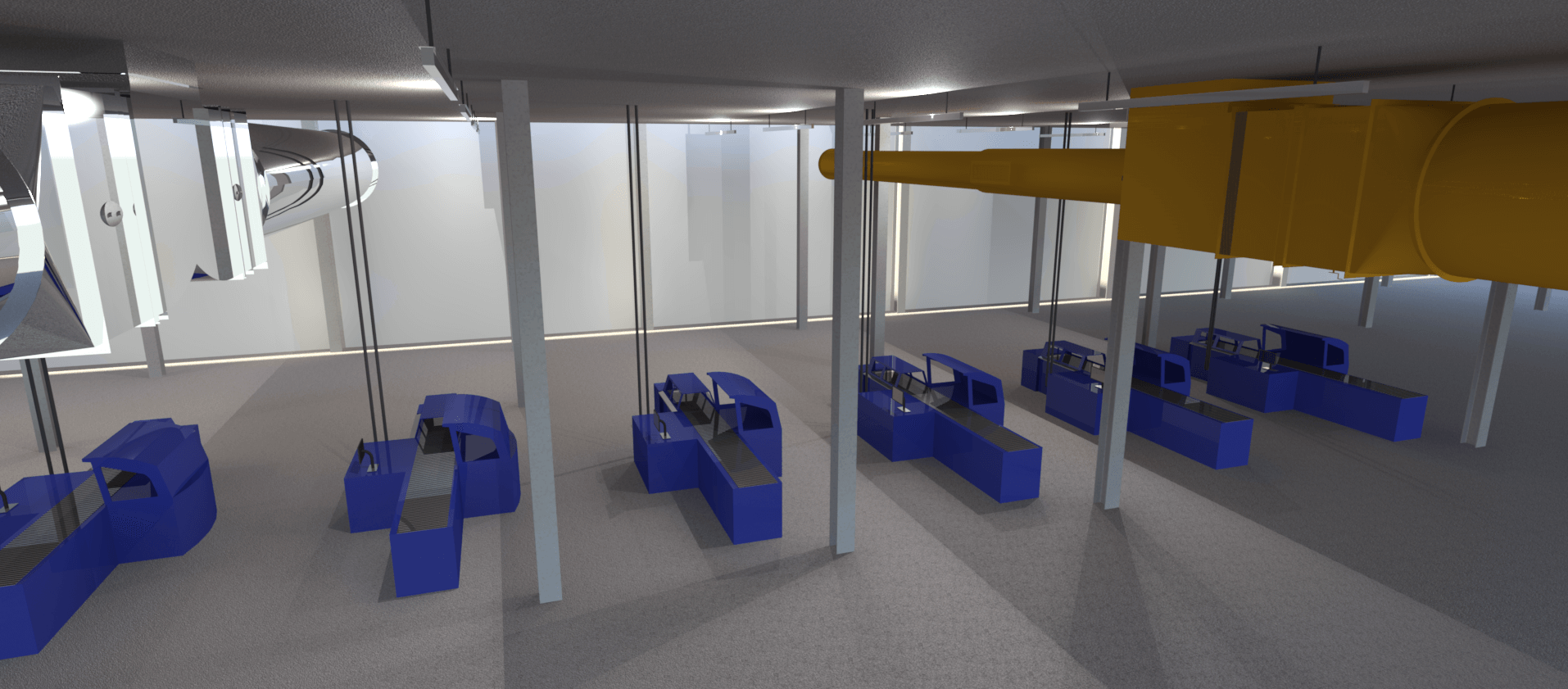

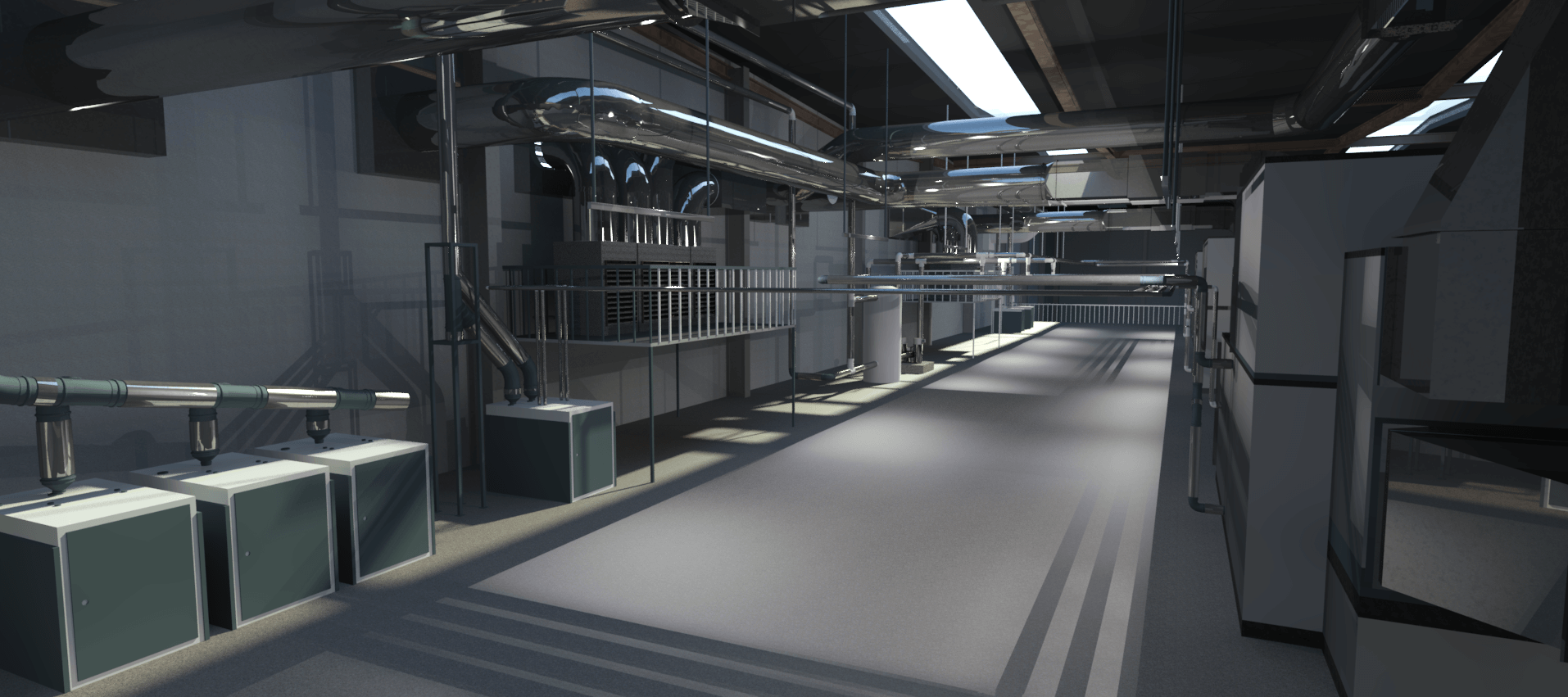

- Ventilation services with heat recovery, humidification, heating coil, cooling coil and air filtration. Supply & Extract ventilation totalling 37m3/s of air.

- Heating services via duty/assist/assist LPHW pumped services exceeding 330kW

- Cooling services via duty/standby chilled water pumped services exceeding 680kW’s

- Gas humidifiers with reverse osmosis and brine treated water, offering over 540kg/hr of steam introduction

- Full site integrated BMS in Tridium software

- Medium pressure gas around 70mBar in the space

- Exhaust ventilation for COSHH due to printer works and gluing process

Challenges

- Meeting tight control in the space of +/- 1.5 degrees C & +/- 5% RH

- Tight programme of circa 16 weeks for all services supplied and installed

- Integration of various services such as Ventilation & Water services in a tight area.

- Installation of ductwork on a mezzanine roof that could not be installed onto suspension from over 8m’s up.

Solution

To design the solution from bottom up with all bespoke equipment and ductwork to suit the client’s needs.

The tight programme dates posed as a challenge for the project, we therefore had to increase the delivery team to overcome this. We employed skilled and qualified engineers, due to the bespoke nature of project, to upskill and train current ATS staff.

Result

A quality installation on each level and service to provide the client will full autonomous Industrial Temperature & Humidity control. It can adjust to all conditions in the space to all deliveries, changes in printing whilst maintaining the set design conditions.

The result was a happy client, with a full production zone, causing no delays to any works.