ATS Electrical were required to Design & CDM Project Manage the Installation of both a Form 4 Control Panel and the lighting for this Wastewater Project.

Client – Wastewater Treatment Site

Project Scope & Objectives

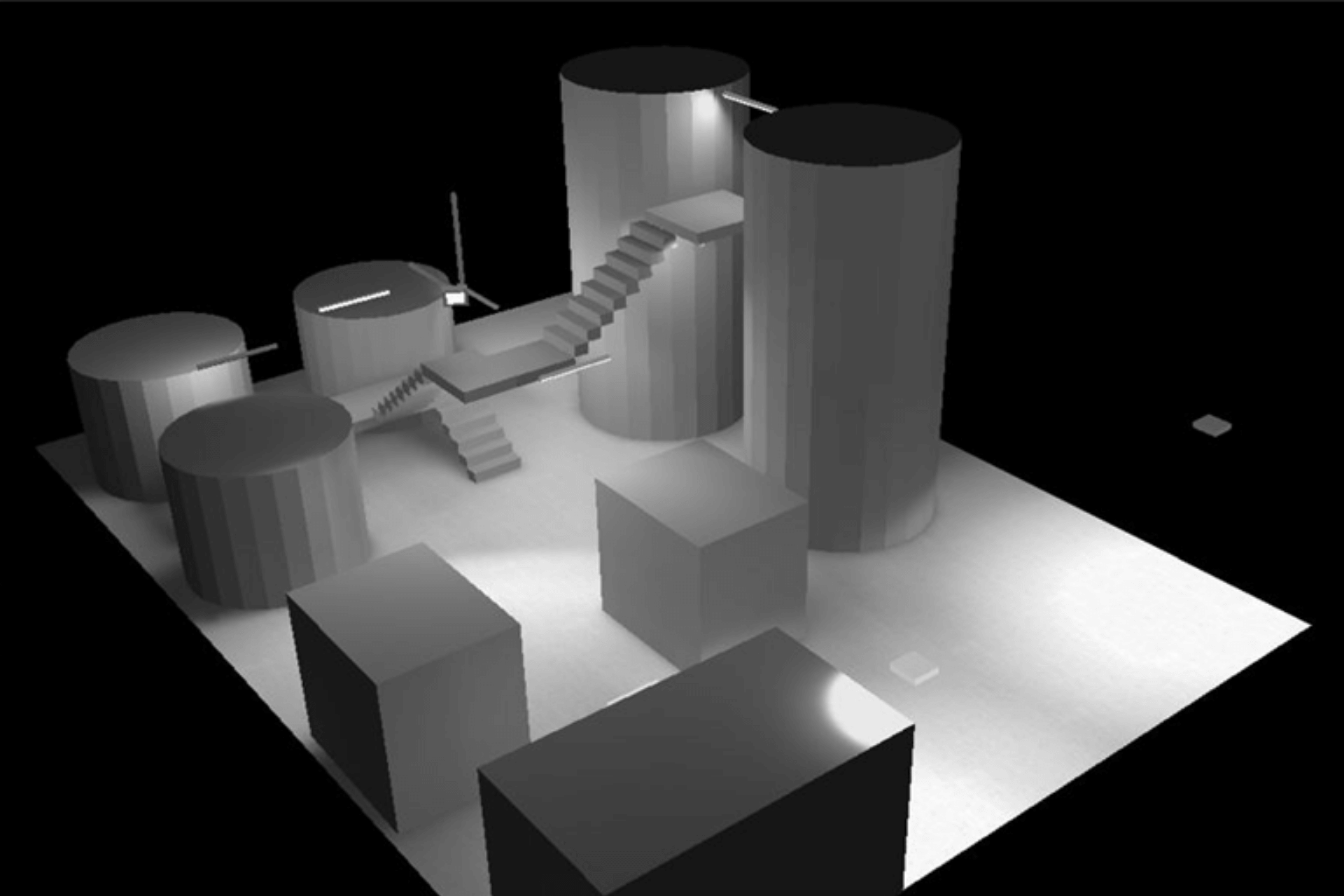

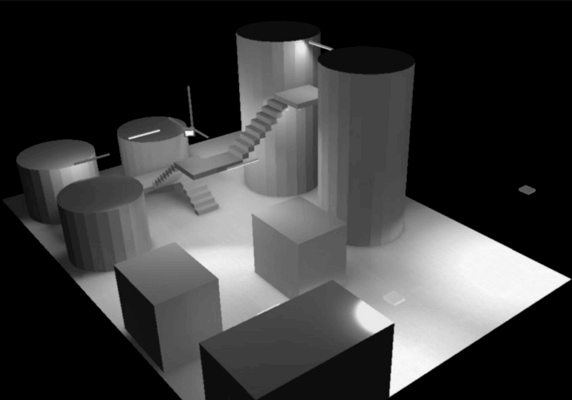

The design and installation of a Form 4 control panel and electrical installation to WIMES and specific water industry specifications. It needed to control a new odour control system, comprising of 2no. biological filter units, 1no. droplet eliminator, 2no. duty stand-by centrifugal exhaust fans with emergency stop, heat extraction, thermistors, flow switches and motor heaters, 3no. carbon filter units, 2no. pressure transmitters, motorised water supply valves, trace heating and panel heaters and flow and limit switches.

Additionally, Air Technology Systems took on the Construction Design Management (CDM) role for this project, completing the removal of redundant PLC code and HMI mimics relating to old plant and new SCADA signals to be integrated with existing site wide system.

Air Technology Systems were also awarded the design, supply and installation of emergency and task lighting to cover the extent of the new installation.

Challenges

Due to this site being a live site, with a fully working process area and the works involving the replacement of an old system, we needed to utilise and change some of the, already in-place, wiring ducts. This needed to be a fast-paced project delivery to reduce “downtime” of the old system, to reduce odours affecting nearby public areas.

It was essential for us to interface with the clients controls system and their external specialists, to adapt the existing feeders and SCADA system for utilisation and commissioning.

Whilst designing the project, we were also required to install a new Form 4 panel in the new Kiosk, due to increased size and capabilities.

We had to ensure WIMES and specific water industry specification to be met with the panel build and full electrical installation, while large amount of Interfacing with new mechanical odour control plant and existing infrastructure was essential to ensure a smooth all round project delivery.

Solution

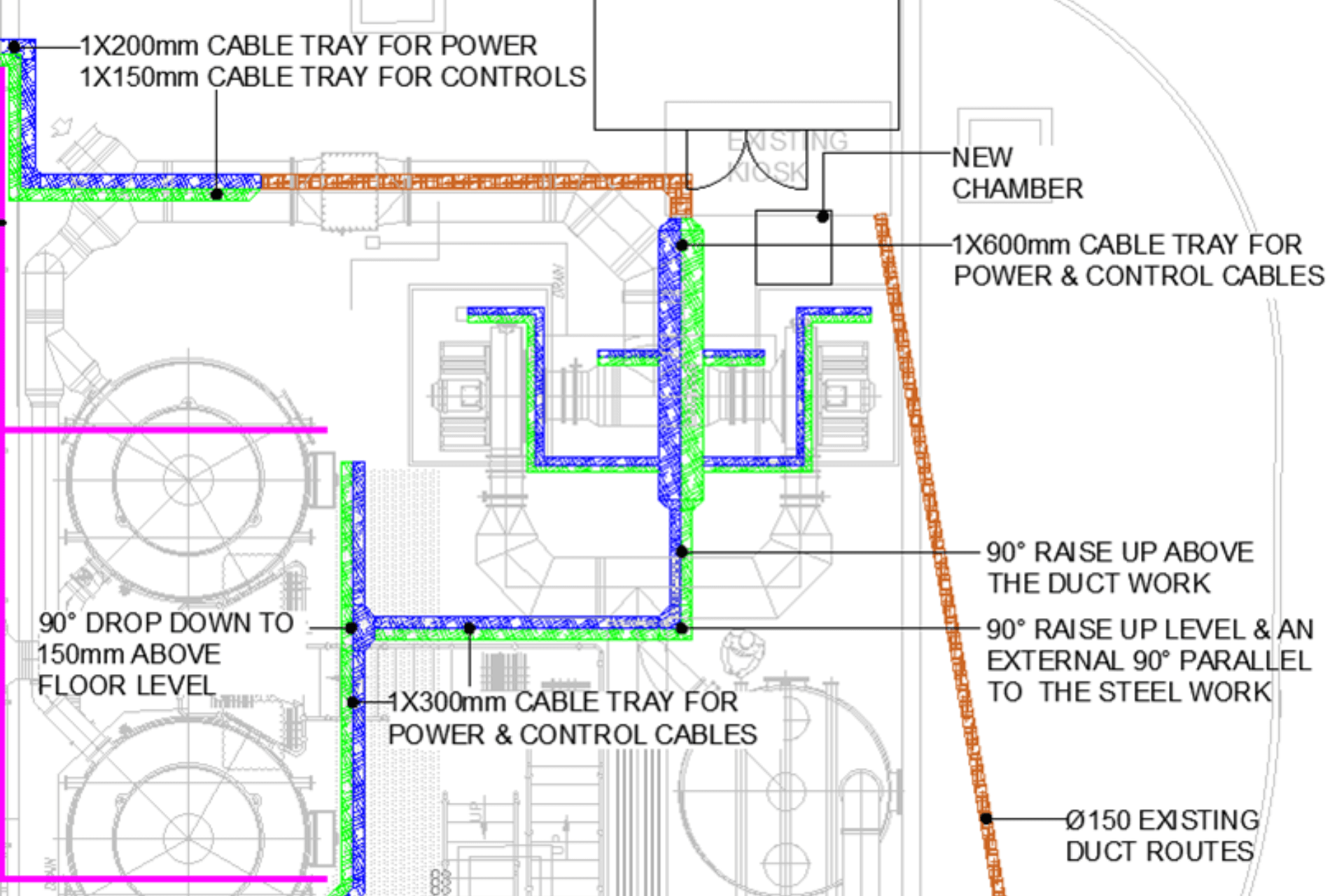

We created new wiring routes with the use of existing wiring ducts and above-ground, heavy duty, post-dipped galvanised tray work to serve all items of kit. This enabled a fast-paced project delivery, while we increased the size of our installation team to reduce overall programme duration.

Due to the complex nature of this project, we positioned on-site, non-working supervisors to assist with smooth CDM project management.

With the new size of Form 4 panel needed, we installed and positioned a new kiosk (4.5m x 2.5m) to house the controls and distribution. To meet with project deadlines, the kiosk was lifted into position after the installation of the control panel, with a temporary waterproof marquee installed to facilitate full installation.

We used our in-house labour team to carry out this project, who have a wealth of experience relating to WIMES and numerous water body specifications, along with our internal Electrical and Mechanical Design teams worked closely to ensure a seamless functional design was provided

Result

As a result of firm teamwork, value engineering and client support; we ensured a fully functional Odour Control and emergency lighting systems were designed, installed, and commissioned to high specification-compliant standards.

We guaranteed both internal and client collaborations, throughout the course of the project, resulting in programme deadlines being met in good time, without any changes to quality or philosophy. At the end of this successful project, all new plant and controls were seamlessly integrated and commissioned alongside local site PLC/HMI and regional SCADA, the emergency lighting installation was installed to a high standard as per design calculations and layout; and tested without issue.